One of the best ways (the best way in my opinion) to get into brewing in the all-grain style is to start brewing one gallon brew-in-a-bag batches! The brew-in-a-bag method uses most of the same principles used in the classic all-grain method but with much less needed space and equipment! This method can be used if you live in an apartment or are simply short on space and/or time.

In this article, I’ll walk you through the steps to make great beer using the brew-in-a-bag (BIAB) method. This specific article will outline a simplified version of the method I use. For the comprehensive ‘How-To’ article, please see my post here. Today’s simplified article will specifically omit water/salt and pH adjustments. Though these are key ways to bring your beer to the next level, you will make quality beer without worrying about the added complexity initially.

Step One: Collect and Clean Supplies

The very first step in brewing using any method is to collect your supplies and clean them. For the BIAB method, you will need the following items:

- Brew Kettle

- Brewing Grain Bag

- Thermometer

- Hydrometer/Refractometer

- Mash Paddle/Large Spoon

- Fermentor

- Airlock/Blow-Off Tube

- Large Pot to heat sparge water in

If you are interested in the items that I specifically recommend for simple and quality small batch brewing, please see my post on my preferred supplies for small batch brewing.

I recommend cleaning everything you are going to use for the actual brewing process including kettle, bag, thermometer, mash paddle/spoon, and large pot with soap and water. It is not a bad idea to sanitize these items; though, technically, as they will all be exposed to boiling water, this is not absolutely necessary. It is okay to wait to clean the fermenter and airlock as you will have ample idle time during the mash and boil later.

Step Two: Add and Heat the Strike Water

Once all your supplies are clean, it is time to add the water. For this beer, I will start with 7.25qt of tap water, which equates to about 1.5 quarts of water per pound of grain. For most of my BIAB beers, I recommend using between 1.25qt water/pound grain and 1.5qt water/pound grain.

My target mash temperature for this particular beer is 152F. For simplicity’s sake, for the majority of beers, you will want to mash between 148-152F as this is the temperature that both of the main enzymes to convert complex starches to fermentable sugars are active at.

For your strike water (the water that the grain will be added to), I recommend heating to about 7-8 degrees hotter than your target mash temperature of, say, 150F. This is because the grain that will likely be at room temperature will cool the water once added.

Step Three: Add Grain to the Brew Bag

Once your strike water is up to calculated temperature, it is time to add the bag and then the grain. Set the bag into the hot water and place the sides of the bag over the rim of the kettle.

Now comes the fun, slowly add your milled grain into the bag. If you have multiple different types of grain in separate containers, I prefer to add each in small increments that way they mix together well. This may or may not make a huge difference in the end, but it has worked out well for me. Stir the grain in well with your mash paddle or spoon as you are adding it, making sure to avoid any clumps.

Brew bag fitted in the brew kettle

Adding the milled grain to the brew bag in the strike water

Step Four: Start the Mash

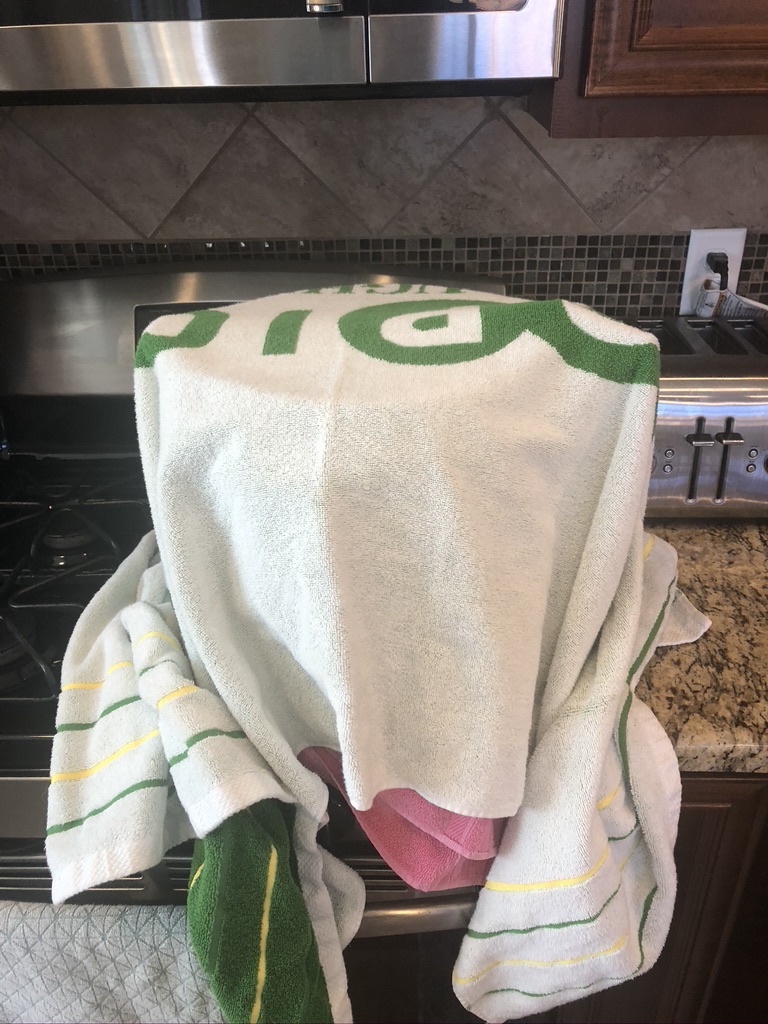

Once all of the grain is added, put the lid on your kettle and wrap it. I have had good success with using beach towels as insulation; however, some people prefer sleeping bags. PLEASE: MAKE SURE HEAT/FLAME IS OFF AT THIS POINT! You do not want towels on fire!

I like to wrap the kettle fully with one towel, securing with a clamp, and then draping another towel on top and around the kettle.

Large beach towel wrapped around brew kettle

Larger beach towel draped on top

Set a timer for 60 minutes. You are literally just going to let the beer sit for one hour. Feel free to take care of anything you need to during this time, but I would personally recommend opening up a homebrew or a nice commercial example of the beer style you are brewing!

If you’re really looking to be productive, you can use this time to clean anything you need to including the kitchen to make your wife, husband, roommate, brother, sister, dog, etc. happy!

Weighing out your hop additions is also not a bad idea at this time.

This is also the time to collect 1.5 gallons or so of sparge water in a separate large pot and heat to 175F-178F. Sparge water is the water that you are going to rinse the left over sugars out of the grain and into your pot to be boiled.

Step Five: Sparge the Grain

Once the mash has completed, take the insulation and lid off.

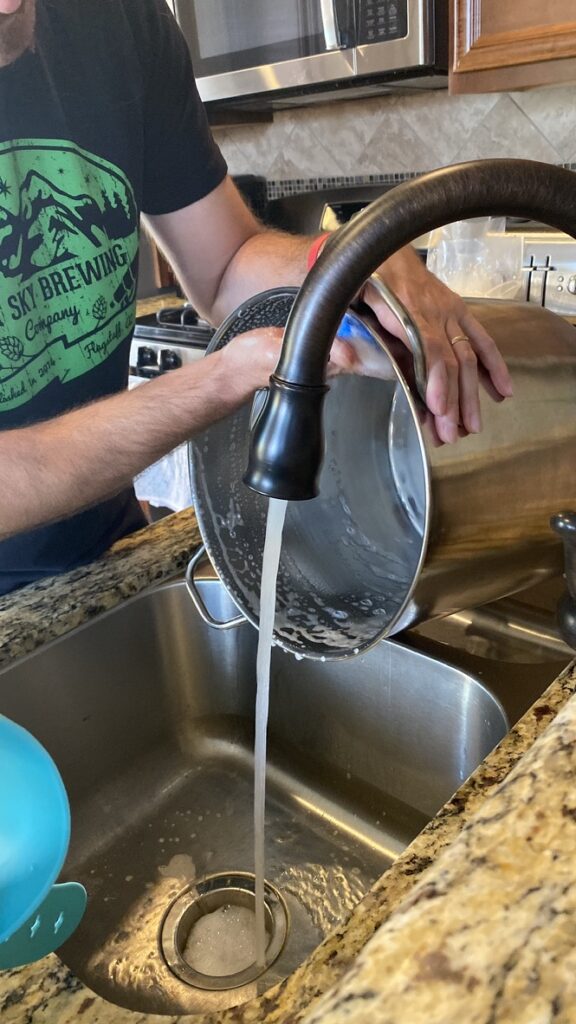

The time has come to sparge. The simplest way that I have found to sparge the grain is to get a colander that fits over your kettle, place the grain bag into said colander, and pour sparge water over this grain, which then falls back into the kettle. You can turn on the burner at this time to start heating the wort to a boil.

I like to use a 2 cup (500mL) measuring glass to pour the hot sparge water over the grain slowly. I find that this gives me good control to not sparge too quickly.

Now don’t feel bad if you have to wear gloves during this step, I have sensitive hands, and I’m not afraid to admit it! Turns out, homebrew does not taste any better with burnt hands.

I like to sparge to about 1.75 gallons for a typical 1 gallon batch. This generally takes about 0.75-1 gallon of sparge water as a decent amount of water is absorbed by the grain. Protip: etch small markings on the inside of your brew kettle for at least the 1, 2, and 3 gallon levels so you can easily see where your volume is at while sparging or boiling.

Step Six: Start the Boil

Once you have sparged the grain and have a volume of 1.75 gallons of wort in the kettle, it is time to start the boil. The nice part about sparging in the formerly stated manner is that the wort is likely already halfway to boiling by the time you are finished sparging.

Some people, including myself, do prefer to use a product like FermCap at this time, which helps to prevent boil-overs throughout the boil (it also helps to prevent excessive krausen development during fermentation).

Once you have a steady boil, you can start your hop schedule. For this beer, I have a very simple hop schedule including a single 60 minute addition and a single 20 minute addition.

For beers that I want on the clearer side, I prefer to use a small addition (1/5tsp-1/4tsp) of Irish moss at the 10-15 minute mark. Remember that during the boil, hop and other additions count backwards- meaning a 60 minute addition is added with 60 minutes left in the boil, not after 60 minutes have elapsed.

While the wort is boiling is a great time to clean and sanitize your fermenting vessel and supplies. I prefer to use a no-rinse sanitizer such as Star-San. In my humble opinion, this type of sanitizer makes things far more simple. Pro-tip here, have a mixture of Star-San in a spray bottle at all times so you can quickly sanitize anything!

With about 15 minutes left in the boil, it’s a good idea to prepare your chilling/cooling supplies. The simplest and most cost-effective chilling method is the classic ice-bath. I have dealt with immersion chillers and plate chillers, but for small batch brewing, nothing beats the simplicity of an ice-bath.

I generally get two regular bags of ice from a local grocery store or gas station, but I usually only need about 1.5 bags for a 1 gallon batch. Using this much ice, I generally get to ideal yeast pitching temperature within 15 minutes or less.

Step Seven: Cool the Wort

Once you have completed your boil, carefully move your pot to the ice-bath. I like to make a whirlpool with the spoon during cooling, as this seems to speed cooling along a bit. This is also the time that you can add whirlpool hops if your recipe calls for it.

During this time, it is important to try not to get any impurities in the wort. Try to limit talking/breathing over the wort, limit pet exposures in the kitchen, etc.

Step Eight: Pour Wort into the Fermentor and Pitch Yeast

Once you have the wort cooled to ideal yeast pitching temperature, you can pour the wort into your sanitized fermentor. If you are interested in the fermentors that I prefer to use, again, you can check out my supplies post. Now is a good time to take a specific gravity reading either with your hydrometer or refractometer. This is your original gravity, please write this down.

If you used a no-rinse sanitizer, such as Star-San, there may be a bit of left over foam- important to remember, DO NOT FEAR THE FOAM! It is okay for your beer to come into contact with some left over sanitizer-foam.

Now comes an often overlooked step, which can be very important for yeast replication and overall survival- wort oxygenation. There are fancy setups for oxygenation that may very well provide superior results; however, I have found that shaking the fermentor carefully but vigorously for a full 1-2 minutes at this time leads to great results. It is important to perform this in a safe manner, I certainly don’t want anyone dropping a full glass fermentor on the floor (even if it is a small 1 gallon one).

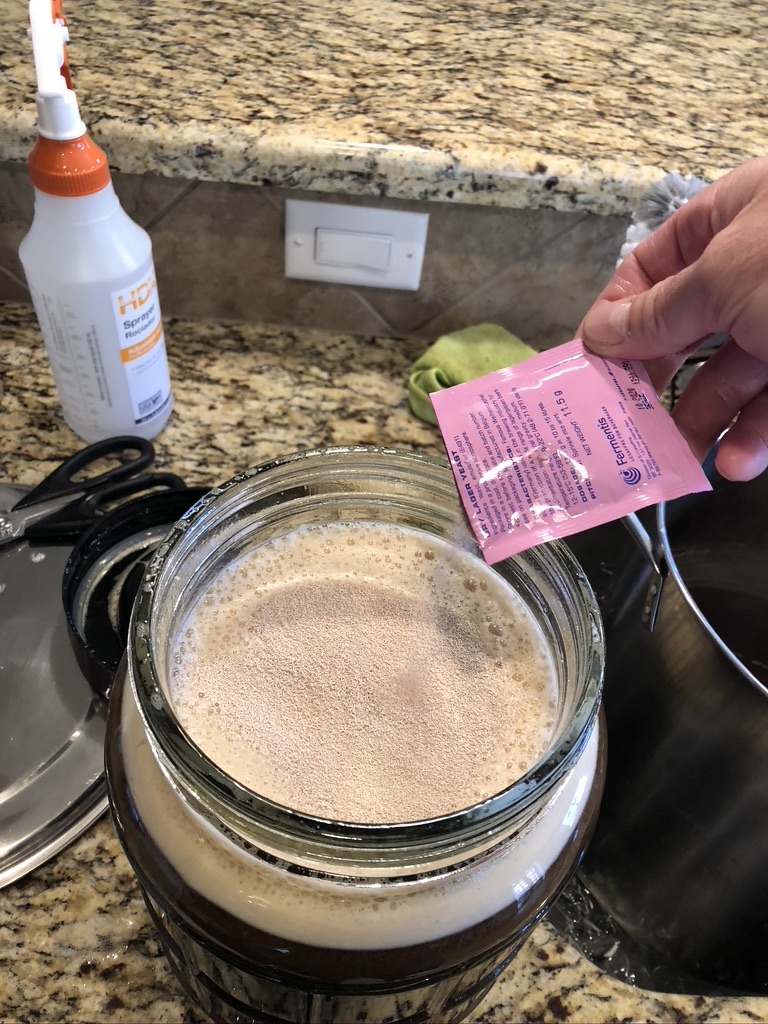

Once the wort is nice and oxygenated, you can pitch the yeast. Depending on the yeast type, you may have rehydrated the yeast first or you may just be directly pitching it into the beer. Remember that most yeast packets are designed for 5 gallon batches of beer. I generally pitch about 1/3-1/2 of a regular packet of yeast for average strength beers. However, for larger (higher alcohol strength) beers, sometimes I use up to a full packet.

It’s worth keeping in mind, though, that if you are desiring a certain strong yeast characteristic, this may be restrained by pitching more than enough yeast- i.e. some of these yeast characteristics develop when the yeast is somewhat stressed by having a lower starting population.

Remember to sanitize your yeast packet as well as the scissors that you will be using to cut the yeast packet open with.

Now you will want to put either an airlock or blow-off tube on the top of your fermentor. You can either add sanitizer or vodka to the airlock/blow-off tube.

Step Nine: Let the Beer Ferment

Now comes the most difficult part for many homebrewers- waiting for the fermentation to proceed. It is important to choose a fermenting location in your house/apartment/cabin/tiny home/bungalow that has a fairly stable temperature within the ideal range of your yeast. You want to pick a location that the temperature does not vary widely throughout the day and night and that is dark overall. However, if sunlight seems to be the only issue, a cardboard box or similar over the top of the fermenter works wonders!

Depending on the type of beer and yeast used, fermentation can take anywhere from 5 days to several months to complete. For the majority of beers, I like to let them ferment for about 2-3 weeks. The correct way to go about knowing if your beer has completed fermentation is to take gravity samples.

If your beer has completed fermentation, the specific gravity (now called final gravity) should remain the same across several days. I will be completely honest, most of the time these days, if the gravity is near predicted and the beer has fermented for 2.5-3 weeks, I generally call it good and package the beer.

For information on bottling the beer, please see my post on bottling.

Congratulations! You have made a beer in the all-grain style. Now that you have the basics, you can get very creative and start making all styles of beer successfully! Once you are comfortable with the information contained in this article and would like to take the next step into playing with salt additions and pH adjustments, please follow this link here to my comprehensive BIAB article.

If this style of brewing seems more complicated than you are interested in at this time, please see my post on 1 gallon extract brewing!